For most manufacturing companies the aim is to maximize efficiency and minimize downtime. But also, it is also premordial to use systems which align with the manufacturing needs of the company while also being easy to use, robust and customizable. Therefore choosing the right automation software for your industry plays a huge role on the performance of your plants and machines. This is why in this article we will be comparing two of the best automation software for manufacturing companies especially those operating in the Brewery industry.

On one hand we have Brewmaxx by Proleit. This is an object-related and PLC-based process control system with MES functionality and integrated recipe control for liquids. Brewmaxx is configure specifically to suit the needs of Companies in the Brewery industry. This means various process steps of the Brewery process can be automated, controlled and Monitored through the software components of the Brewmaxx range.

On the other WinCC SCADA by Siemens is a supervisory control and data acquisition(SCADA) and human-machine interface(HMI) system form Siemens. SCADA systems are used to monitor and control physical processes involved in industry and infrastructure on a large scale and over long distances.

In this article we will compare Brewmaxx and WinCC SCADA by going through seven features of these software which are engineering, technology, robustness, availability, communication, diagnostic and security.

Features

1.Engineering

Brewmaxx(Maximum engineering efficiency): Brewmaxx provides an integrated engineering environment you can rely on in all phases of the lifecycle of the machinery and plants performance. Brewmaxx provides Efficient software supports over the complete lifecycle of your machine or plant from the planning and design stages through configuring as far as commissioning, operation and upgrading is required. With its integration capability with harmonized and vertical interfaces, Brewmaxx software supports a high degree of data consistency throughout the entire engineering process. Proliet has redefined engineering with its automation software tools in a unique development environment through :

- Making the whole process is based on configuration not programing therefore reducing project lead time

- Reducing Minimum uptime and limiting downtime for new integration, most at time plant extension don’t require any shutdown.

- Introducing multiuser and parallel engineering on the same project

2. Technology

Brewmaxx(More possibilities, less complexity): Brewmaxx provides integrated technology functionalities which does counting,measuring,cam control, closed-loop control and motion control. With Brewmaxx you can integrate technological tasks in many different combinations and with various degrees of complexity without a system changeover. Brewmaxx creates a technological platform which is easy, convenient and consistent in which parameter assignments and configurations are implemented in a familiar environment.

WinCC SCADA(Less possibilities): Though WinCC SCADA through integrated technology usually support integration of single machine unit SIMATIC Wincc which is easy and convenient to use. Parameter assignment and programming are required to implemented a simple project

3. Robustness

Brewmaxx(Maximum industrial suitability): Products from Proleit provides high robustness this is why each standard

product from the PlantiT or Brewmaxx range is characterized by the highest quality and robustness and is perfect for use in industrial environments. Specific system tests ensure the planned and required quality is produced. brewmaxx components meet all relevant international standards and are certified accordingly.

WinCC SCADA(built for quality): SIMATIC Wincc is built to serve the purpose of quality. For demanding to extreme rated conditions, special versions such as SIPLUS extreme or special versions of SIMATIC software are available. These include an increased degree of protection, extended temperature ranges, and exceptional environmental stress.

4. Availabity

Brewmaxx(Maximum availability): Brewmaxx provides a comprehensive high availability concepts which is used by the entire plant: From the field level to the control level all the way up to the management level. For example, field-tested controllers ensure high availability through bumbless switching with automatic event synchronization.

WinCC SCADA(Highly Available): WinCC SCADA being an industrial software of international standards also provides high availability through all levels.

5. Communication:

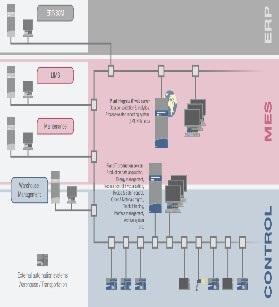

Brewmaxx(Maximum data transparency on all automation levels): Based on proven standards Brewmaxx creates the

foundations for unlimited integration in communication and scalability. This thus is a perfect environment for maximum transparency on all levels. This stretches from the field and control level to the operations management level all the way up to the corporate management level. Brewmaxx relies on international, cross-vendor standards which can be combined flexibly: PROFINET, the leading Industrial Ethernet standard and PROFIBUS, the global.

WinCC SCADA(Limited data transparency): Wincc has limited Transparency on all automation levels. This is due to the SIMATIC standards which isn’t a great foundation for integration in communication and thus limited transparency on all levels, in the field and control level right up to corporate management level.

6. Diagnostics:

Brewmaxx(Minimization of Downtime): Brewmax uses efficient diagnostics concepts which is integrated all through the software. This makes is such that a fault can be identified and eliminated to provide increased system availability. Even with larger plants, the maintenance station provides you with a uniform view of the maintenance-relevant information for all automations.

WinCC SCADA(Minimization of Downtime): Wincc SCADA uses high quality diagnostic concepts which detects fault through out the automation processes and machinery. This are easily identified and communicated or eliminated to reduce the amount of the downtime machines go through and maximize efficiency of performance of plants and machinery.

7. Security:

Brewmaxx(Data security in the networked world): Through harmonized, scalable security systems due to the increased use of Ethernet connections penetrating the field level,security issues are gaining in importance in industry. For comprehensive protection of a plant, a variety of suitable measures must be implemented. These range from the company organization and its guidelines regarding

protective measures for PC and control systems through to protection of automation cells by segmenting the network. ProleiT follows the cell protection concept and, with its series cyber security modules, brewmaxx offers components for building up protected cells.

WinCC SCADA(Minimization of Downtime): Siemens follows the cell protection concept and, with the modules of the SCALANCE with WinCC series Wincc , offers components for building up protected cells.

Conclusion:

Brewmaxx and Wincc SCADA are both world class industrial automation softwares which will render your machnirery,plants and processes they perform more efficient and avoid any production issues. However, we see Brewmaxx as a system which is easier to use with less programming and more configuration. Also, given that Brewmaxx is a software which was purposefully created for companies operation in the brewery industry, it is optimize to breweries and provides a software tailored to their needs. This makes it the perfect go to solution for companies in the brewery industry.